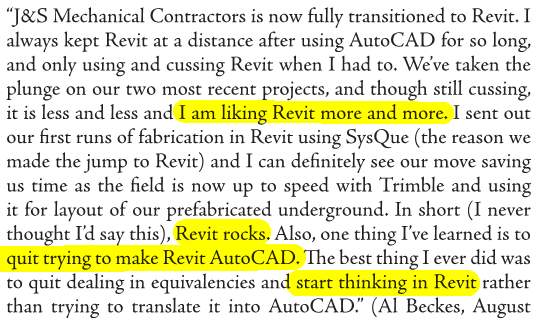

Revit lets you model things that you can’t necessarily build, which shouldn’t surprise us given that “Revit was intended to allow architects and other building professionals to design and document a building” 🙂 wiki

However, in recent times Revit is getting used more and more for fabrication workflows, with core Revit features, addins, and Dynamo scripts developing to make that happen.

With that in mind, I was shared something recently and simply had to share it… check out the video below:

Basically it shows how we can quickly cut up impossibly long modelled Revit elements (like Pipes) into more ‘buildable’ fabrication lengths. Cool! The video also discusses how appropriate generic fabrication content could really begin to bridge the gaps between Revit models and actual things you can buy off the shelf.

Thanks to Nathan Moore for sharing this! And credit also to Jeremy Tammik and Pablo Derendinger.

I think we will inevitably see more and more automations like this that connect Revit to real fabrication and procurement workflows. Feel free to share your thoughts and ideas in the comments!

From the video comments:

Are you paying for a Revit M/P Fabrication add in or using ITMs to route and coordinate to LOD400? I think there is an opportunity to use native Revit to accomplish this. A properly “parameterized” fitting family combined with the correct pipe types and routing preferences would allow native Revit to produce what you need.

Dynamo Script here:

https://github.com/natethegrate1/MEPTools/blob/master/place_coupling.dyn

Credit to Jeremy Tammik and Pablo Derendinger:

https://thebuildingcoder.typepad.com/blog/2020/03/splitting-a-duct-in-more-depth.html

https://engworks.com/revit-dynamo-script-to-cut-pipes-and-ducts/

Some related thoughts and ideas from Nate here, pointing out a common problem with modelling generally (that in order to model accurately, you often have to select some kind of proprietary brand / make / model first):

I am in a situation (and I think most other companies are in similar situations) where I am not necessarily the final decision maker on the “BRAND” of pipe/fittings that we end up buying. There is a fundamental disconnect I think in the industry that fabrication software providers want to provide MANUFACTURER SPECIFIC items to help streamline the downstream purchasing/install/warehousing operations… My solution is to create a “SPEC DRIVEN” family library (similar to how duct works) so I can simply have an “ASTM SCH40 Welded” system or a similar Grooved system etc. That way the families placed will adhere to the spec and allow more flexibility downstream for the buyers/warehouse.